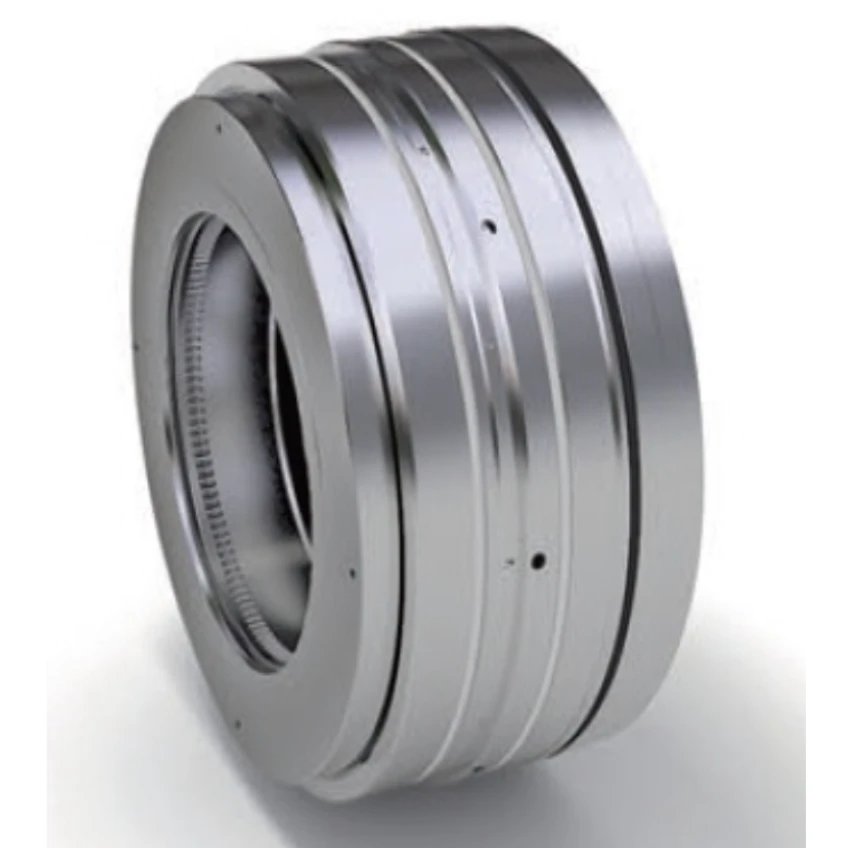

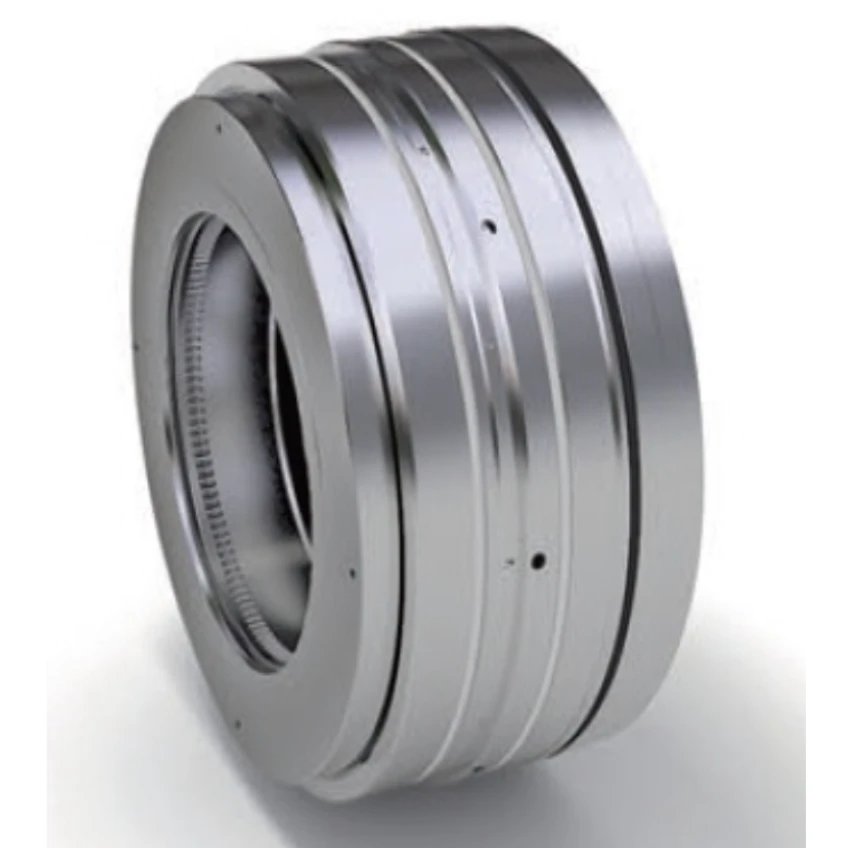

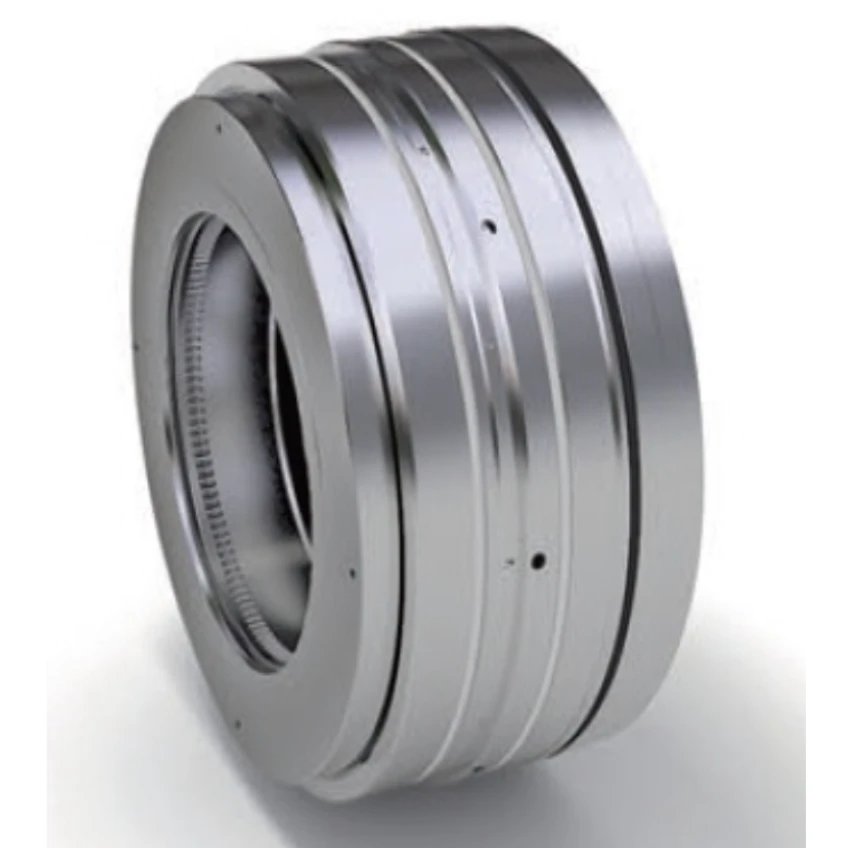

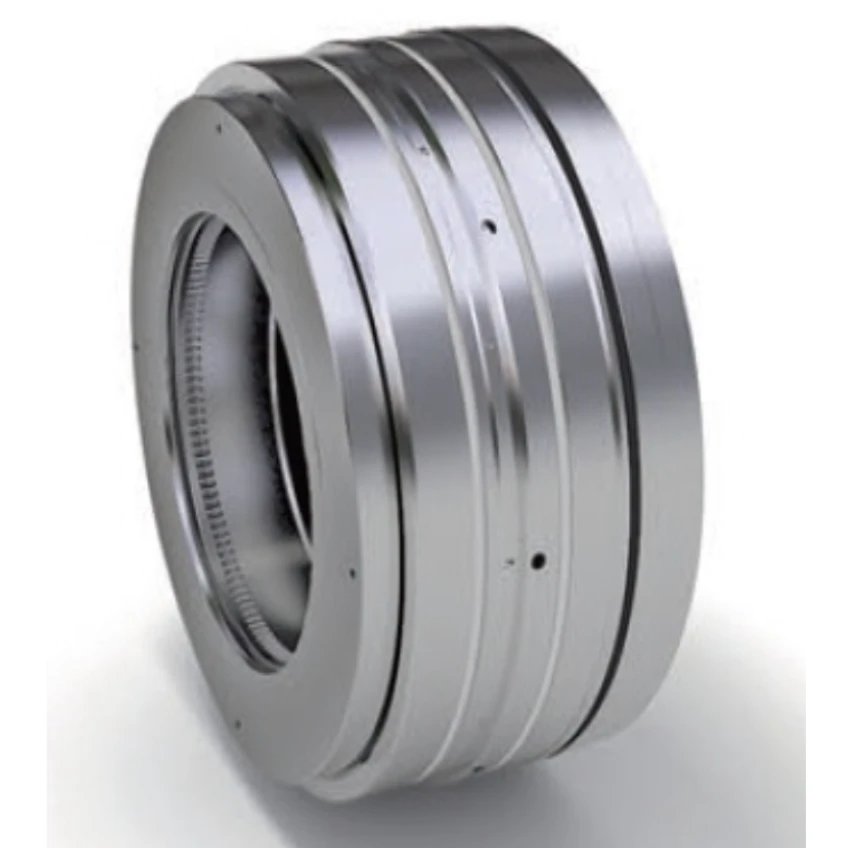

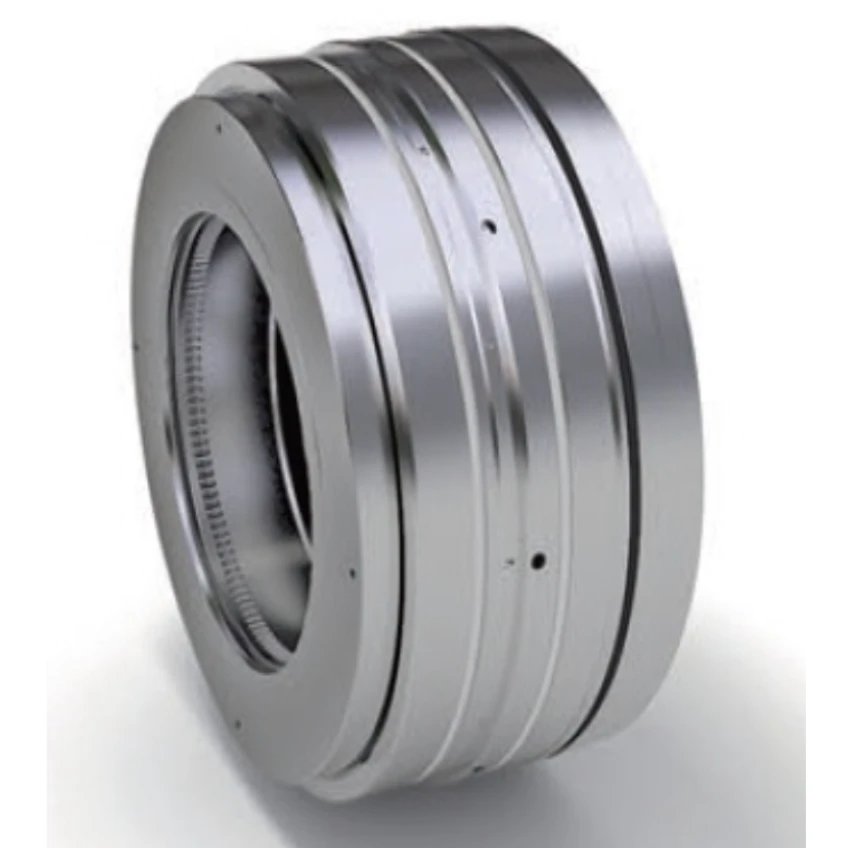

Dry Gas Seals Power Plants

At HQ, we are renowned for our high-performance dry gas seals, engineered specifically for power plants. Our advanced manufacturing capabilities, extensive factory space, and 30+ years of expertise ensure that we provide reliable and cost-effective sealing solutions. With a commitment to innovation and quality, we cater to over 10 countries, offering customizable products that adhere to international standards. From design to delivery, our skilled team guarantees optimal performance and client satisfaction in every project.

Discover Our Pricing